SECURE AI

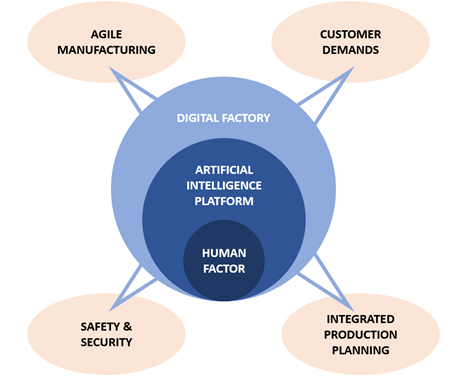

The pilot aims at implementing, validating and demonstrating secure, safe and transparent human-centred AI processes, which will be deployed across the IBER-OLEFF company's (Portugal) production areas (i.e. injection, decoration, assembly, validation, etc.) that are associated with the production of an air-vent for the automotive passenger compartment. The pilot emphasizes product customization that underlies the disturbances of the production process. Due to variations in monthly orders, the production process will have to be tailored to customer needs but will also allow for planning linearization without increasing unfinished product inventories, increasing productivity and reducing costs.

- UC1 – Agile Production Management System Data Integrity and Reliability: This UC will take advantage of STAR’s security and data governance technologies in order to ensure the integrity, confidentiality, availability, non-repudiation and authenticity of industrial data used by AI systems and processes. Techniques for decentralized validation of industrial data will be employed, notably techniques that audit/validate datasets derived from sensors and unreliable data sources. Likewise, the UC will leverage the project’s cyber-defence techniques against Deep Neural Networks, with emphasis on confronting attempts for contaminating machine learning and deep learning algorithms.

- UC2 – Production Processes Simulations for Accelerated Decisions and Safe Processes: This UC will develop human-centred digital twins that will simulate production processes in real time, towards identifying scenarios that ensure safety and achieve the required flexibility. The digital twin will enable the high-level planning and management systems to access detailed real time information from the production line, in order to get the general state of any production cell for effective real-time optimization.

- UC3 –Production Planning Linearization: This UC will linearize production planning towards reducing the work peaks and consequently the number of extra work hours, but also towards reducing production down times as well. It will leverage advanced online process sensing/ monitoring systems and different parameters and variables into the manufacturing process and products. To this end, non-destructive testing techniques will be employed in order to measure dimensions and defects, while contactless and agile technologies will be incorporated.

- UC4 – Employ Training for Reduction of Human Errors: Human factors play a predominant role in IBER’s production processes i.e. the processes are not fully automated. Hence, training of human resources in the various production processes will be planned and carried out in advance, in accordance with appropriate operational methods. This will lead to improvement of operative methods and consequently to the reduction of human errors associated with learning and assimilation. Moreover, due to continuous monitoring of production processes, human errors associated with overspecialization (i.e. when an operator is performing the same functions in the same workplaces over a given period) will be reduced. Practically the phenomenon can be described as the loss of operator concentration due to overconfidence, with consequences on productivity and quality of work performed.